reprinted from Automotive Engineering, January 1989

Honda revives turbo

Honda's success in Formula One Grand Prix racing with a generation of turbocharged 1.5-liter engines should long remain legendary in the history book of motor sports. Curiously, Honda abstained from the production car turbo application since the demise of the furious City Turbo II mini runabout several years ago.

With the formula change coming in effect in 1989, Honda is tackling the Grand Prix racing with yet another unique power plant, a quad-cam, naturally aspirated 3.5-liter V10 engine. On the other hand, it is applying its considerable accumulation of turbo technology in a production car, a Japanese version of the suave Legend sedan.

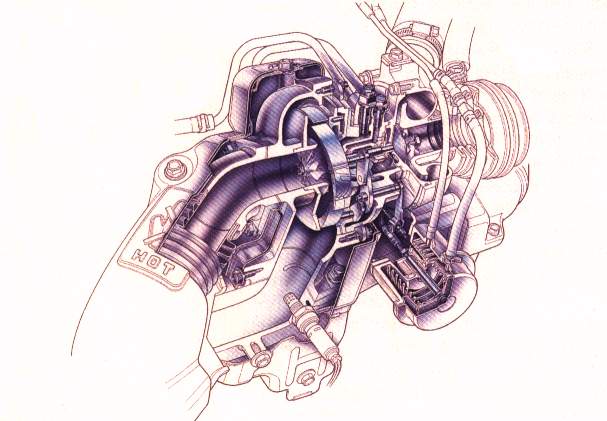

Called "Wing Turbo," the instrument is a variable geometry turbocharger of Honda's inhouse design and manufacture, that employs four pairs of stationary and pivoted movable wings in the turbine housing. The wings are made of heat resistant Inconel alloy.

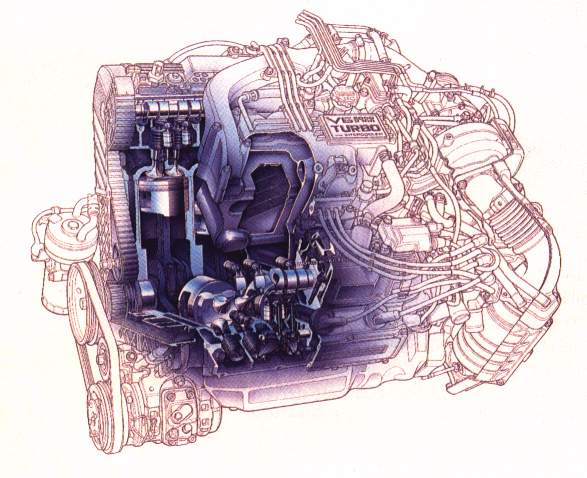

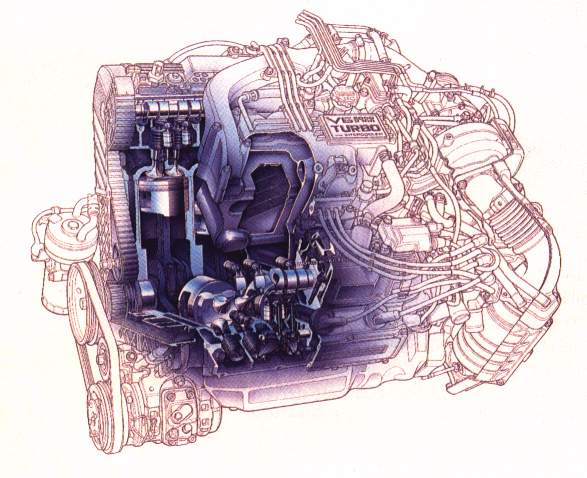

|

| A watercooled intercooler is situated between the banks. |

The movable wings are positive pressure- and vacuum-operated, their angle changes are controlled by an eight-bit 36-kilo byte computer that also manages fuel injection. Positive pressure to the wing actuator is supplied by the turbo's supercharge pressure, controlled by a frequency solenoid valve, and negative pressure is generated by intake vacuum and accumulated in a reservoir which is also solenoid controlled. The CPU is fed signals including boost pressure, intake temperature, coolant temperature, throttle opening, engine rpm, and vehicle speed. The Wing Turbo is not fitted with a conventional wastegate.

On idling and steady-state cruising that do not require supercharging, the movable flags--or wings--which are fully opened, allow exhaust gas to enter the enlarged nozzle area and pass through the turbine smoothly with little resistance. At the beginning of full acceleration, the wings close fully, reducing the nozzle area through which accelerated gas enters and strikes the turbine blades forcefully, gaining boost quickly. When maximum boost is obtained, the movable wings begin to close gradually, until the vehicle reaches a desired cruising velocity whereby the wings open fully. The nozzle area varies continuously according to operating and load conditions.

|

| Honda's variable geometry "Wing Turbo." |

As installed on the two-liter version of Honda's 90° four-valves-per-cylinder V6, a maximum boost of 450 mmHg is reached at as low as 2000 rpm, improving the engine's torque output and response on rapid acceleration. Combined with an electronic ignition control, employing knock sensors, the Wing Turbo allows an unusually high compression ratio of 9.0:1, contributing to the engine's high output as well as good fuel economy.

The 2-L Wing Turbo engine is fitted with Honda's PGM-FT electronically managed fuel injection, and its boosted air is intercooled by a watercooled intercooler mounted between the cylinder banks. The intercooler water is cooled by a separate radiator and circulated by its own pump; the system has a cooling capacity of 5600 k-cal/h, and lowers intake air temperature by as much as 36°C.

|

| One of four pairs of wings is seen in its fully open position at idling speed and steady-state cruising, letting exhaust gas flow through with minimum resistance. |

The Wing Turbo V6 produces 142 kW JIS net at 6000 rpm and a maximum torque of 241 N·m at 3500, which are superior to those of the naturally aspirated 2.7-liter version that powers senior (and U.S.) Legend models which are by the Japanese ratings 134 kW and 226 N·m, respectively. If there is any penalty in the Wing Turbo installation, it is probably an added weight; about 40 kg over the straight-forward two-liter V6.

The Wing Turbo V6 is mated to Honda's electronically controlled four-speed automatic transmission, and drives the front wheels of the four-door sedan.