"In automobile development, the weight reduction is and always has been a significant and challenging issue. When the weight of the engine itself is to be reduced, the proportion of the weight reduction accounted for by the cylinder block is very large and thus very necessary," asserts Honda. The company has been vigorously developing and producing engines, many of whose major components are aluminum, particularly cylinder blocks. It adds, "Cast iron sleeves are being used as cylinder liners in more aluminum engines; this is an obstacle to further weight reduction." Some of the solutions Honda suggests are use of 1) a hyper-eutectic aluminum-silicon alloy (A390), 2) an aluminum liner on which Ni-SiC powdered dispersed plating is applied, and 3) a metal matrix composite, any of which enables the production of a linerless light-alloy cylinder block. At present, its cost is prohibitively high and its manufacturing process too complex for volume-production vehicle models.

So the more-commonly used technology is separate iron liners cast in the aluminum block, which in Honda engines requires at least a 9 mm minimum distance (web) between cylinders. These factors determine an engine's outer size in proportion to its cubic displacement, and there lies, literally, a rub.

In more practical considerations, Honda was readying its first compact sports utility vehicle, the CR-V, which would be produced, including its aluminum engine, at the company's Suzuka factory, the home of Civic cars. In fact, the CR-V, though a considerably larger vehicle, belongs to the broad Civic strategy that the company was pursuing, and that would produce more variants and derivatives.

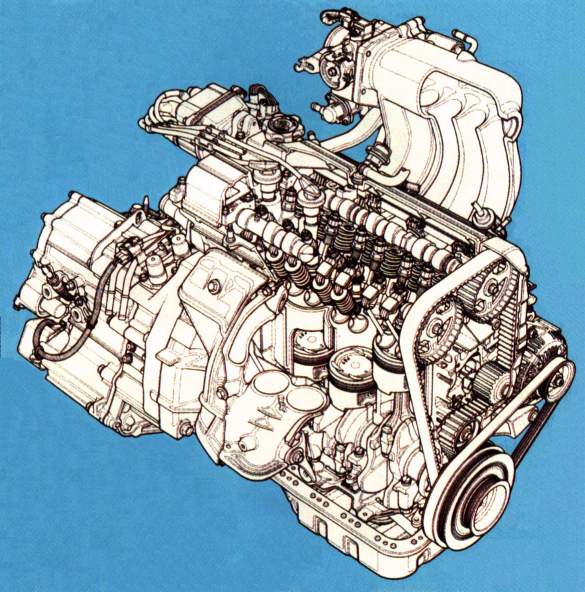

The CR-V, with good off-road capability, would need an engine with about a 2.0-L displacement. Honda's type F20A engine of the Accord family, with its width of 694 mm, would not fit in the shell, and comes from another factory source. The engine must be of the compact type-B family, for the sporty Civic and Integra cars. The type B16A 1.6-L unit, and the B18B 1.8-L version, shared the same block with with the engine's overall width of 601 mm. The B18B's 1834-cc capacity was obtained by stroking the B16A to 89 mm. Further enlargement to a planned 2.0-L capacity could only be achieved by increasing the bore of the B18B, however, the engine's high-pressure die cast aluminum block with separate iron liners left no room for such enlargement. Thus the development of a new one-piece cast liner unit with four integrally cast cylinder liners came about, which Honda describes as "consecutive liner construction," or "quad-sequential sleeve block." It is more like Siamese-quadruplets. With this liner construction, the web distance, or distance between the inner walls of the adjoining cylinders, could be reduced to 6 mm from the separate lines' 9 mm, while retaining the same bore pitch. This was the essential requirement so that the new block could be cast and machined on the existing Suzuka lines. This enabled the addition of 3 mm to the bore, to 84 mm which, combined with the B18B's 89 mm stroke, increases the engine's cubic capacity to 1972 cc. Further, the increase in block mass is only 0.8 kg, from the B18B's 25.3 kg to 26.1 kg. Efforts were made to shave mass from other internal and external components of the B20B, achieving the end result of a total dry mass of 144.5 kg for the new engine, to the smaller displacement B18B's 148.1 kg, making it one of the lightest in its displacement category.

There were a number of technical problems that accompanied the new block construction that had to be solved. The main problems and solutions were as follows:

A senior Honda engineer says that mono-liner casting techniques had been presented in papers, the oldest by Ford to his knowledge, and some six years ago by Daihatsu; however, one has reached actual product application. Honda has applied for 13 patents comprising 44 items, according to the engineer.

Jack Yamaguchi

1972 cc. This is made possible by the novel casting

technique allowing thinner walls between cylinders.

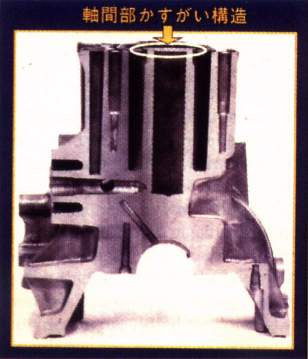

cast-in quadruple-Siamese iron liners.

(top) and the new quadruple-Siamese

liner unit.

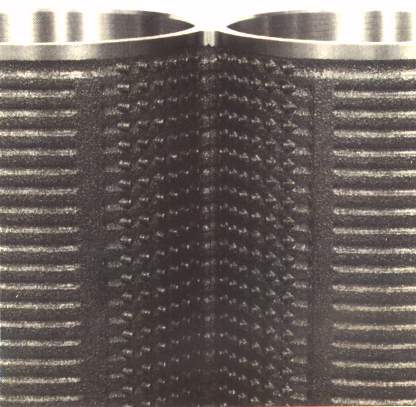

ensure tight bonding of the liner

with the aluminum block.

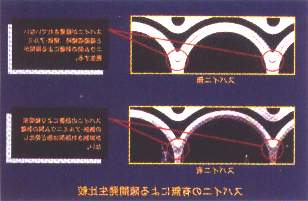

casting when conventional ribbed liners are

cast are shown at top. Lower portion shows

tight bonding between the two different

materials when spined liners are used.

die diverts contracting force from the casting.

It is removed when the block is machined.